| Capacity | 5T/D |

| Power | 46.99KW |

| Installation size | 7.5x4x3.8m |

| Finished product | Four size grits |

| Dust density | ≤10mg/m³ |

1.Automatic whole line can save workers, one person can be available for operation.

2.Complete function processing as cleaning maize, peeling maize, and grinding maize into maize flour and maize grits.

3.Clean maize to remove stone, metal, sand and all sorts of impurities.

4.Peel maize to remove maize skin, remove maize germ, remove black maize . After cleaning and peeling, it prepares best maize material for further processing into maize flour or grits.

5.You can choose the mesh to make the flours fine as you requirement.

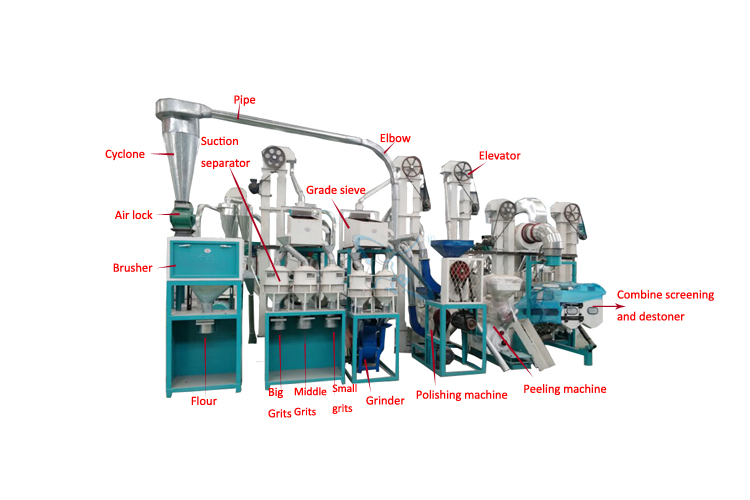

Complete maize flour milling machine have Four stage.

1.Cleaning stage.

Use the magnetic separator removing the iron. The vibrating screen is mainly used to remove the impurities, and then use the destoner removing the stone and other impurities.

2.Peeling stage

Emery roller peeling machine is used for peeling the maize . after removing the shell.

3.Grinding and Milling stage

Grinding and milling the maize. And then use the double -bin plansifter screening .

4.Packing stage

Finally the final product will be packed.

Delivery time:20 days after pay for the deposit

Packing: shipping container