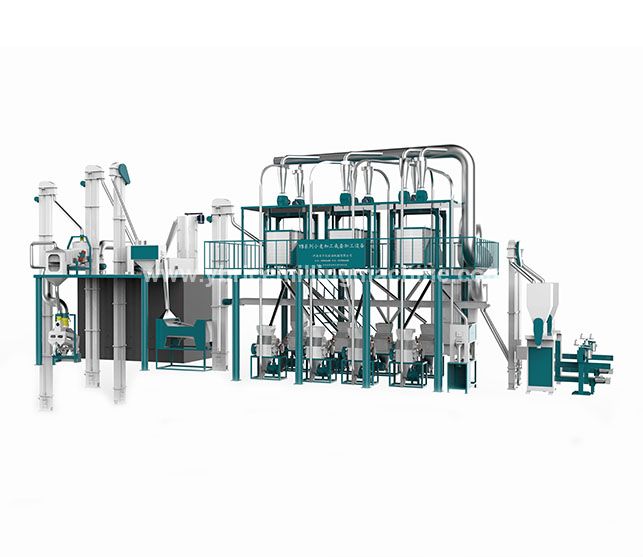

| Type | 6F2240 | 6F2250 | 6F2260 |

| Capacity | 200-300kg/h | 300-400kg/h | 500kg/h |

| Power | 13.2KW | 18KW | 19KW |

| Installation size | 2.54*0.8*3.2m | 2.64*0.8*3.2m | 2.74*0.8*3.2m |

| Powder fineness | 60-90mesh | 60-90mesh | 60-90mesh |

| Dust density | ≤10mg/m³ | ≤10mg/m³ | ≤10mg/m³ |

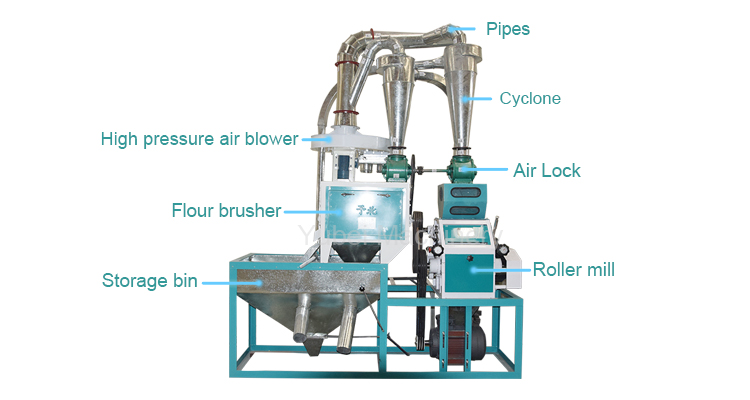

1.Automatic feeder,continuous milling,reduce the labour intense.

2.Wheat skin and wheat core will be milled separately.

3.Pneumatic conveying can reduce the dust which improving the environment of working.

4.Easy operation and maintenance,

5.Good safety performance, high efficiency, less investment,quick recovery, thus greatly favoured and evaluated by the users.

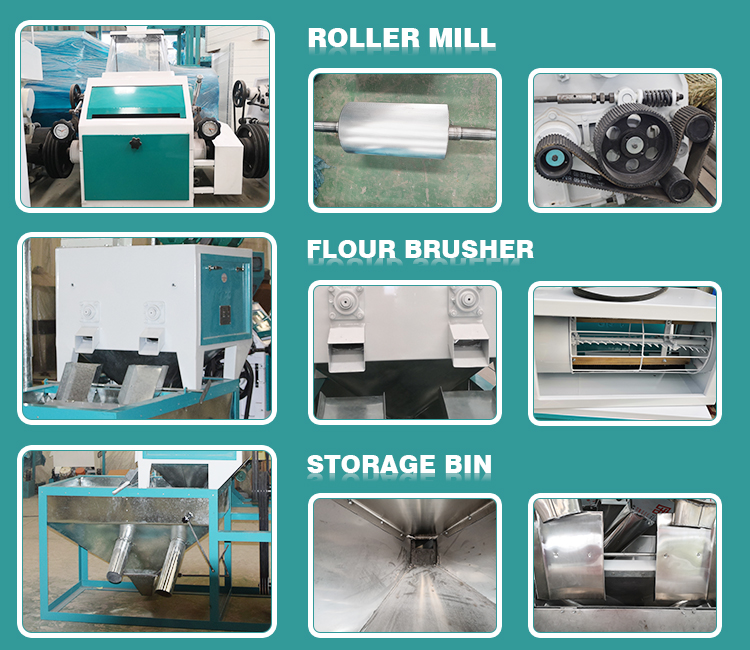

Wheat skin and wheat core are milling independently in this milling machinery.

The raw material enter the machine are grinded for 4-5 times , the flour out ,the skin will be continue grinded ,the flour out, the skin out. Next grinding the core for some times, the flour out.

Delveiry time:15 days after pay for the deposit.

Packing: Plywood case.